Material Unloading Equipment

Efficient and Reliable Material Unloading Equipment for Business

Unloading of materials is an integral part of any warehouse or manufacturing logistics operation; efficient unloading helps keep productivity up and prevents the scenarios of downtime. Material unloading equipment is crucial in terms of the efficient shift of flow of goods, decreasing the number of manual labor hours necessary to put the goods into position, and getting goods placed in the right place safely. This encompasses unloading of bulk items or pallets and even fragile items where correct machinery could be a difference maker in operational efficiency.

What is Material Unloading Equipment?

Material unloading equipment includes tools and machines to unload cargo from a truck, container, or delivery vehicle into a warehouse. These devices are there to eliminate workplace accidents, increase speed, and ensure a smooth process. From a basic pallet jack to conveyor belts and automated systems, the following comprise the set of tools that guarantee material handling safety for final speed and efficiency.

Different Types of Material Unloading Equipment

- Pallet Jacks: Manual or electric pallet jacks are usually used to unload palletized goods. Pallet jacks are ideally suitable for transferring within a relatively shorter distance within a narrower space.

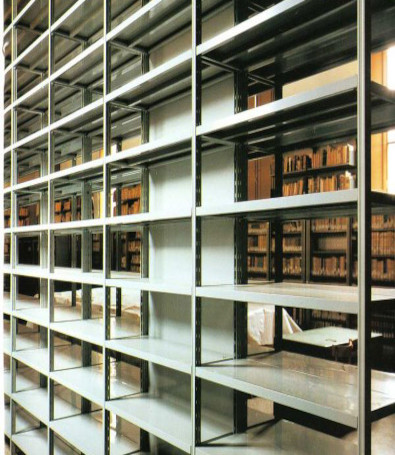

- Forklifts: Forklifts are huge machines that can handle heavier shipments, and thus it is required for a huge warehouse or an industrial site. They can be utilized to unload materials that have been offloaded from a truck and put on storage racks or shelves.

- Conveyor Systems: The conveyor systems applied, can automatically shift materials from one location to another, ensure efficient unloading for bulk goods, and avoid manual labor.

Benefits of Material Unloading Machines

- Increased Efficiency: The right unloading equipment will be able to hasten the process, minimize downtime, and ensure that your goods are delivered fast and safely to their destination.

- Lower Labor Cost: Automating or simplifying the unloading process often saves on the use of manual labor, thus reducing operational costs.

- Better Safety: Using the appropriate unloading equipment minimizes the risk of workplace injuries, especially when heavy or bulky materials are involved.

- Better Precision: Material unloading equipment helps ensure materials that get handled in the right way do not suffer damage during unloading.

Reach out to us

If you are seeking ways to improve your material handling operations with quality unloading equipment for materials, we can help. Our unloading equipment and systems are engineered to improve the effectiveness, safety, and productivity of your business. Contact us today to learn more about our products and how we can help you smooth your unloading processes.

Our Products

Efficient Products

for Your Business

Why Choose us

Top Quality Shelving is The

Most Complete

and Varied

-

Durable & Heavy-Duty Construction

-

Tailored to Your Needs

-

Trusted by Industry Leaders

-

Exceptional Customer Support

Get in Touch

TESTIMONIALS

Client Testimonial

What Our Customers

Say About Us

I've been using Heavy Duty racking for over a year now, and I'm incredibly impressed with its durability, versatility, and the fast installation services provided by Symo Trading. I'm a small business owner, and I was initially hesitant to invest.

Before I had Normal Racks, my storage area was a mess. Inventory was scattered all over the floor, making it difficult to find anything and increasing the risk of damage. Mobile Shelving has allowed me to maximize my vertical space.

Bolt Free Shelving has made it incredibly easy to organize my inventory. The adjustable shelves and dividers allow me to customize the storage solution to my specific needs. I can now easily categorize and locate items, which has saved me.

I highly recommend Symo Trading to anyone looking for a durable, versatile, and easy-to-install storage solution. It has been an invaluable investment for my business, and I'm confident that it will continue to serve me well for years to come.